Product Spotlight: Internal Retaining Rings

Internal retaining rings act as a removable shoulder within a bore/housing. These internal rings come in a variety of configurations. For applications that require an internal retaining ring, Smalley offers Spirolox® or internal spiral retaining rings, Hoopster® rings, constant section rings, and WaveRings®. This blog post explores the differences between these internal retaining rings and highlights potential applications for each.

Spirolox® or Internal Spiral Retaining Rings

Spirolox retaining rings are an alternative to a stamped retaining ring. Unlike a traditional stamped ring, Spirolox rings are designed without ears or lugs. This prevents any interference with mating components and creates a uniform cross section. Instead of using the ears or lugs for installation and removal, these rings can be wound into a groove and removed with a simple screwdriver. No special tools or pliers are required for installation and removal. This design is achieved by coiling flat wire through a process called Edgewinding™. To create a stronger retaining ring, consider increasing the number of turns, wire thickness and adjusting the radial wall. Rings with at least two turns also provide a 360° retaining surface. To learn more about the installation and removal process of Spirolox rings, check out our video here.

Standard Spirolox® rings are separated into categories based on the load required for the application. These categories are as follows: Light (VH and VHM series), Medium (WH series), Medium Heavy (WHT series), and Heavy (WHM series). The DNH, EH, and VHM series are all Spirolox rings that are specifically designed in metric sizes. DNH, EH, WH, and WHM series of rings are specifically designed to meet the quality specifications for Military and Aerospace applications

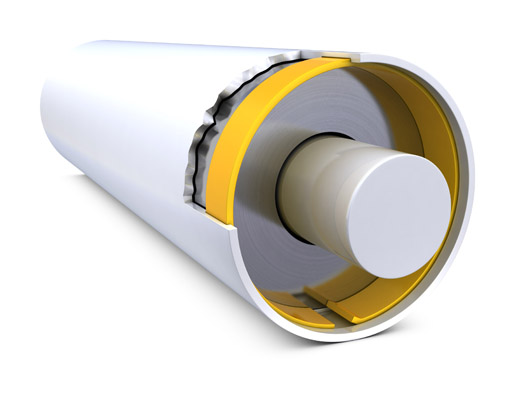

Below is an application where a Spirolox internal retaining ring is used.

Bike Lock – Two-turn Spirolox Retaining Ring

This heavy-duty or WHM internal ring is used within the bike lock because of its thick cross-section. This ring was designed with the orientation of the removal notch facing inwards, eliminating the possibility of removal. This specific design prevents tampering with the lock and theft.

Constant Section Rings or Snap Rings

Constant section rings are a heavier duty retaining rings that are also coiled from flat wire. These rings are specified for impact loading applications and can typically be found in automotive or industrial assemblies. Internal constant section ring series are FHE and the XAH. The XAH series rings are interchangeable with Eaton style snap rings. The metric equivalents of both are the FH and XDH series. Internal constant section rings are available with a wide variety of end types from U-Notch to Scalloped. A complete list of constant section end types can be found here.

Below is an application that uses two constant section rings.

Actuator Valve – Constant Section Ring

The heavy-duty XAH internal constant section ring was specified because of its ability to absorb the shock loading of the pistons. This application required a ring designed to withstand a high thrust and a ring with special ends due to the location of the ring within the assembly

Hoopster® Retaining Rings

Hoopster® retaining rings are designed with an extremely low profile and are used in applications with limited space. These internal retaining rings offer minimal radial projection and can operate within a shallow groove. Internal Hoopster rings are classified depending on whether or not the ring is designed with bent ends for removal. The HHU (imperial) and HHMU (metric) series are designed without a removal notch, meaning the ends nearly meet to create a perfect circle. In contrast, the HH (imperial) and HHM (metric) series are designed with a removal provision so one end of the ring is slightly crimped. This makes it easier to remove the ring inside a housing. Below is an example of an application that features a Hoopster internal ring with bent ends as well as one without.

Thin Walled Cylinder – Hoopster Ring

This cylinder required a retaining ring to hold the two components together. However, the assembly did not offer enough space for a standard retaining ring groove. A Hoopster ring was selected due to its low profile and the shallow groove depth. The cylinder on the left shows a standard HHU ring with bent ends whereas the cylinder on the right shows a HH ring with standard ends.

WaveRing®

The Internal WaveRing® series (WHW) is a unique style of retaining ring. These rings have a wave allowing them to compress as well as perform similarly to a standard retaining ring. WaveRings can compensate for extended tolerance of stacked components. These rings can reduce vibration within an assembly. This is possible because the WaveRing is applying pressure against the groove and against the assembly components. Custom WaveRings are also available in a single turn configuration.

Gear Bracket – WaveRing

In this application, the WaveRing® acts as a hybrid between a retaining ring and a wave spring. It retains the bracket together while allowing for slight compression in the assembly. This specific Wave Ring is designed in a two-turn configuration and features a removal notch.

Summary

Smalley offers a variety of standard internal retaining rings, from Spirolox to WaveRings. But did you know that any of these rings can be customized for your application? Material thickness, alloy, number of turns, and end type can all be designed to meet your specific application requirements. Challenge a Smalley engineer to design an internal retaining ring for your application. Check out our new Retaining Ring FAQ to learn more about our Spirolox Retaining Rings.

Connect With Us